Hemp Fiber: A Boon for Sail Making and Hull Construction

Hemp fiber, derived from the stem of the cannabis plant, has been used for centuries to make various products, including clothing, paper, and rope. However, it is particularly well-suited for sail making and hull construction due to its unique characteristics. In this article, we will explore the history and benefits of hemp fiber in sail making, as well as discuss its advantages in hull construction. We will also examine the challenges and limitations of using hemp fiber and its potential as an environmentally sustainable alternative to synthetic materials.

History of Hemp in Sail Making

Hemp has been used in sail making for thousands of years. The earliest known use of hemp sails dates back to ancient Egypt, where they were used on ships for trading and transportation. In the 16th century, hemp sails became popular in Europe due to their strength and durability, which made them ideal for long sea voyages. The use of hemp sails continued until the 19th century when cotton sails became more prevalent. However, hemp has recently experienced a resurgence in popularity due to its sustainability and superior performance compared to synthetic materials.

Benefits of Hemp Fiber for Sail Making

Hemp fiber has several advantages over other materials commonly used for sail making. Firstly, it is incredibly strong, which means that it can withstand the stresses of high winds and rough seas. Secondly, it is lightweight, which is essential for achieving maximum speed and maneuverability. Thirdly, it is resistant to rot and mildew, which is crucial for maintaining the longevity of the sail. Finally, it is also easy to work with, making it a popular choice for sail makers.

Characteristics of Hemp Fiber

Hemp fiber is a natural fiber that is derived from the stem of the cannabis plant. It is a bast fiber, which means that it is obtained from the inner bark of the plant. Hemp fiber is known for its strength, durability, and resistance to moisture and salt. It is also lightweight and has a natural luster that gives it a unique appearance. Due to its natural properties, hemp fiber is an excellent material for sail making and hull construction.

Strength and Durability of Hemp Fiber

One of the significant benefits of hemp fiber is its strength and durability. It is an incredibly tough material that can withstand harsh weather conditions and the stresses of sailing. Hemp fiber has a high tensile strength, which means that it can resist stretching and breaking under load. It is also resistant to abrasion, which is crucial for maintaining the integrity of the sail over long periods of use.

Hemp Fiber’s Resistance to Moisture and Salt

Another advantage of hemp fiber for sail making and hull construction is its resistance to moisture and salt. Hemp fiber is naturally resistant to rot and mildew, which is essential for maintaining the longevity of the sail. It is also resistant to saltwater, which means that it will not deteriorate over time due to exposure to seawater. This makes it an ideal material for use in marine environments.

Hemp Fiber vs. Synthetic Materials

While synthetic materials such as polyester and nylon have become popular for sail making and hull construction, hemp fiber has several advantages over these materials. One of the main benefits of hemp fiber is its sustainability. Unlike synthetic materials, it is a natural material that is biodegradable and environmentally friendly. Hemp fiber is also more durable and can withstand the stresses of sailing better than synthetic materials.

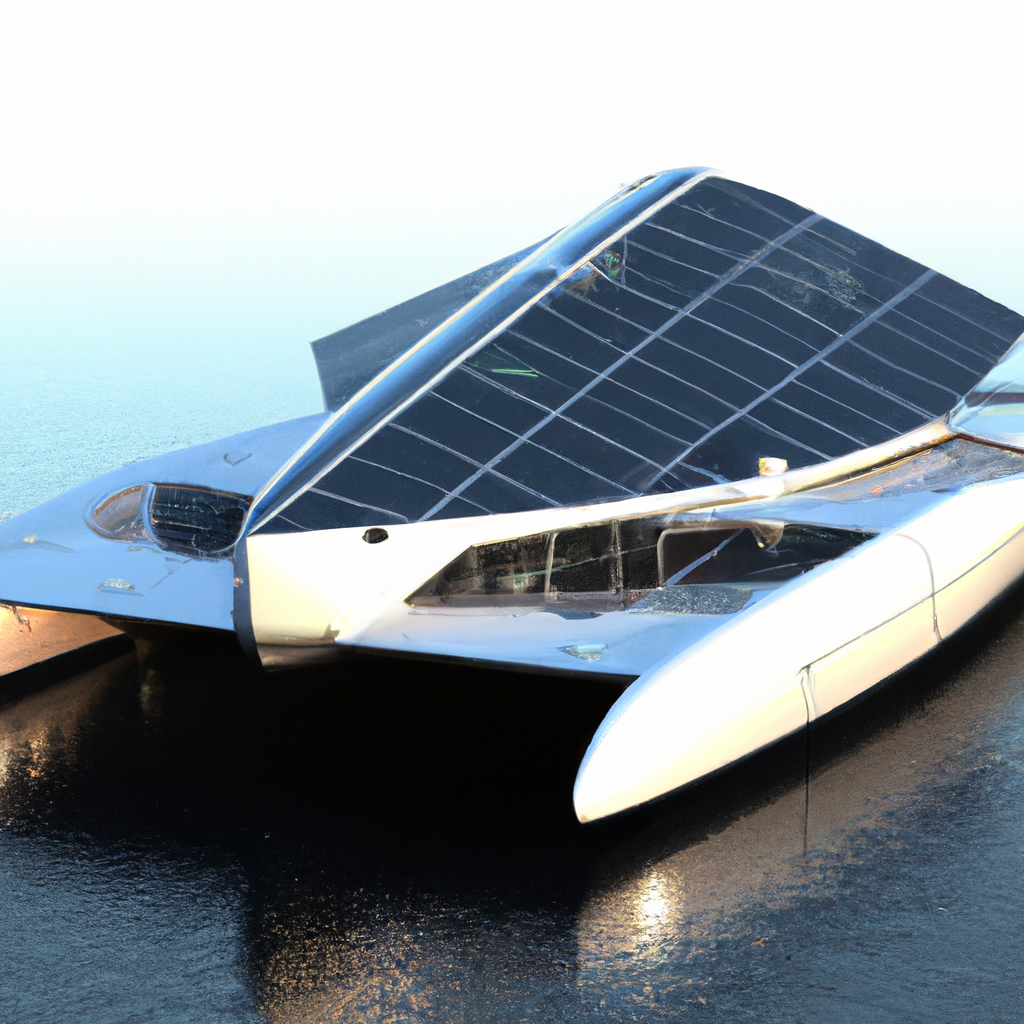

Hemp Fiber in Hull Construction

Hemp fiber is also an excellent material for hull construction. It is commonly used in the production of composite materials, such as fiberglass, to reinforce the structure of the hull. Hemp fiber can also be used in the construction of wooden boats, where it is used as a natural alternative to synthetic materials such as fiberglass and epoxy.

Advantages of Hemp Fiber in Hull Construction

Hemp fiber has several advantages in hull construction. Firstly, it is lightweight, which is essential for achieving maximum speed and maneuverability. Secondly, it is incredibly strong, which is crucial for maintaining the structural integrity of the hull. Thirdly, it is environmentally friendly, which is essential for reducing the impact of boat building on the environment.

Hemp Fiber’s Environmental Sustainability

Hemp fiber is a sustainable material that has several benefits over synthetic materials. Firstly, it is biodegradable, which means that it can be broken down naturally without harming the environment. Secondly, it is renewable, which means that it can be grown and harvested without depleting natural resources. Finally, it is non-toxic, which means that it does not release harmful chemicals into the environment.

Challenges and Limitations of Hemp Fiber

While hemp fiber has many benefits in sail making and hull construction, it also has some limitations. One of the main challenges is its cost. Hemp fiber is more expensive than synthetic materials, which can make it less accessible for some boat builders. Another limitation is the availability of the material. Hemp fiber is not as widely available as synthetic materials, which can make it more difficult to source.

The Future of Hemp Fiber in Sail Making and Hull Construction

In conclusion, hemp fiber is an excellent material for sail making and hull construction due to its strength, durability, and resistance to moisture and salt. It is also environmentally friendly, which makes it a sustainable alternative to synthetic materials. While there are some challenges and limitations to using hemp fiber, its potential as a natural and sustainable material for boat building is significant. As awareness of the importance of sustainability continues to grow, we can expect to see increasing demand for hemp fiber in sail making and hull construction.